|

Xinxiang Great Wall Machinery Co.,Ltd

|

GGBS Vertical Roller Mill

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

GGBS vertical roller mill is the equipment to grind Ground Granulated Blast furnace Slag (GGBS),Nickel slag, manganese slag and so on into small part

Introduction of GGBS vertical roller mill

GGBS vertical roller mill is the equipment to grind Ground Granulated Blast furnace Slag (GGBS) into small particles.GGBS (fineness:4200-4500cm2/g) produced by vertical roller mills are being used to substitute clinker in conventional cement manufacturing, for which the percentage of GGBS usage is typically at 10-15% and 20-25% respectively.

Features:

1. Good return on investment

The widely use of slag increases the market demand to slag gradually. In recent years, investment in slag production line has been a new favorite in investment market. One production line can recover the cost in 1-3years.

2. Reducing the power consumption of slag micro powder preparation effectively.

According to the display of slag powder production measured data, traditional ball mill needs power consumption 75~80kWh for per ton slag micro powder. However, it needs power consumption 42~45 kWh for per ton slag micro powder if adopts advanced vertical roller mill technology, and it can be saving electricity 33~35kWh use of vertical roller mill production per ton slag, and power saving effect is very remarkable.

3. Reducing the environment pollution effectively in the process of slag powder preparation.

Slag powder vertical roller mill adopts the internal negative pressure system to reduce the dust spillover effectively. The equipment adopts advanced technology with low revolving speed, stable operation, low noise, and the noise does not exceed 85dB(A) from the mill 1 meter.

4. Removing iron effectively, increasing additional income.

The advanced technology of slag vertical roller mill can be removed the iron effectively from the slag, and no less than 1% iron content can not only protect the machine, but also can increase additional income.

Learn More By Video

Investment income

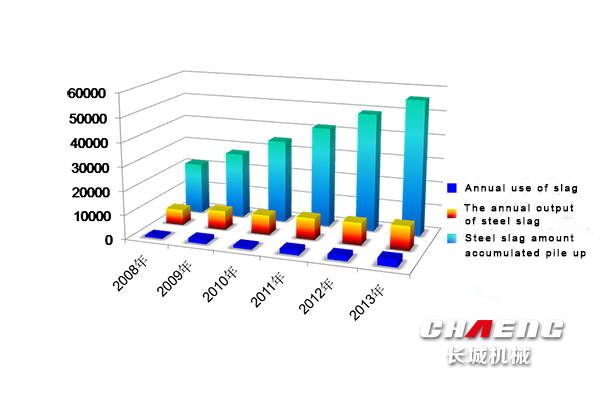

According to association statistics, currently the world each year to produce slag the amount of over 90 million tons, steel slag utilization in 2013 less than 25% , over the past five years the cumulative amount of over 1.279 billion tons discard pile, and the number is increasing, steel companies to environmental management pose serious challenges.Specifications

ModelGrinding Table Diameter (mm)Roller Diameter (mm)Roller Number (n)Motor (kW)Output (t/h)

| Model | Grinding Table Diameter (mm) | Roller Diameter (mm) | Roller Number (n) | Motor (kW) | Output (t/h) |

| GRMS26.21 | 2600 | 1600 | 2 | 1000 | 30 |

| GRMS33.31 | 3300 | 1700 | 3 | 1600 | 50 |

| GRMS35.31 | 3500 | 1800 | 3 | 1800 | 60 |

| GRMS40.41 | 4000 | 1900 | 4 | 2240 | 70 |

| GRMS43.41 | 4300 | 2120 | 4 | 2800 | 90 |

| GRMS46.41 | 4600 | 2240 | 4 | 3150 | 105 |

| GRMS48.41 | 4800 | 2240 | 4 | 3550 | 125 |

| GRMS50.41 | 5000 | 2360 | 4 | 3800 | 140 |

| GRMS53.41 | 5300 | 2500 | 4 | 4200 | 160 |

| GRMS56.61 | 5600 | 2500 | 6 | 5000 | 180 |

Note: mill spectral pattern benchmark

Material medium friction (MFs)=0.9~1.0;

Material moisture max 15%;

Refined powder granularity 4200~4500 cm²/g;

Refined powder moisture 0.5~1.0%;

The concrete mill installed power and technology parameter will be adjusted appropritely basing on the actual material property and requirements of owner;